EPDM O-Ring

Catalogue

EPDM O-Rings (ethylene propylene diene monomer)

O-Rings made of EPDM material can be found a a variety of industrial

applications. EPDM is short for ethylene propylene diene monomer, and it has

a 45% to 85% ethylene content. Improved loading is consistent with a higher

percentage of ethylene content. Crosslink density is higher as a result of

peroxide curing.

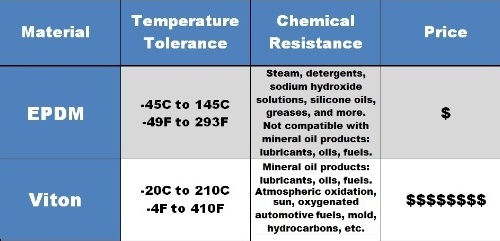

EPDM is compatible with hydraulic fluids, water at extreme temperatures,

ketones as well as alkalis. However, it does not perform well with

concentrated acids, gasoline, most types of oils, and hydrocarbons of both

aromatic and aliphatic types.

Physical characteristics of EPDM rubber are its excellent resistance to

heat, as well as its ability to withstand weathering and ozone degradation.

Satisfactory performance as against steam and polar substances ate also

noted. Electrical insulating characteristics, resistance to ordinary acids

in diluted form, and to alkaline are also satisfactory.

Common applications of EPDM material are found in seals, as in the form of

an insulator for doors used in cold rooms. Other uses include face seals,

where silicone type seals are not recommended. These are typically found in

environments where automotives are been spray painted. However, EPDM

elastomers are most usually found in vehicles as in sealing for doors,

windows and car trunk.

Keywords: Ethylene Propylene O-Rings, Sunlight, Ozone, weathering, Hot Water

and Steam, Auto / Aircraft Brake Fluids, Some Acids and Bases, Ketones and

Alcohols, Plumbing.

Copyright © 2017 Ge Mao Rubber Industrial Co., Ltd.